The Era of an ERP yelling loudly to own your business is over. With the proliferation of the ERP API, here’s what we can look forward to now.

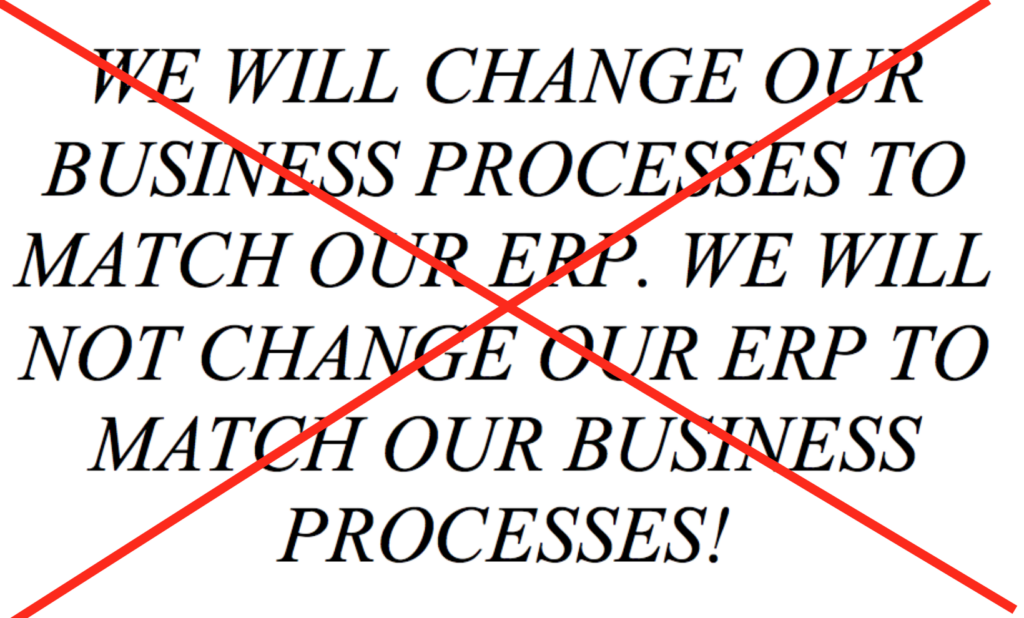

It was the dumbest sign to ever grace my professional life; in 36 point font, taped on the wall of the satellite fabrication office, capital letters proclaimed:

WE WILL CHANGE OUR BUSINESS PROCESSES TO MATCH OUR ERP. WE WILL NOT CHANGE OUR ERP TO MATCH OUR BUSINESS PROCESSES!

I almost thought it was a prank, but it was on official letterhead and signed by a Vice President. So it had to be real, right? How had a respected business gone so far down the rabbit hole to bestow their future decision-making to a lumbering piece of software?

The story starts much further back. In this article, we’ll cover the history of ERP systems, the modern ERP

The History of ERP Systems

From Materials Planning to Software Augmentation

Many people grow nostalgic about the years prior to widespead software adoption and for good reason. Some elements of business truly were better. If a person sold parts, that person had to know how the parts worked and fit into an assembly. In contrast, today’s businesses feature undertrained staff members clicking around to provide an incorrect “solution”. Thus, one can quickly see how nostalgia for pre-computer times originates.

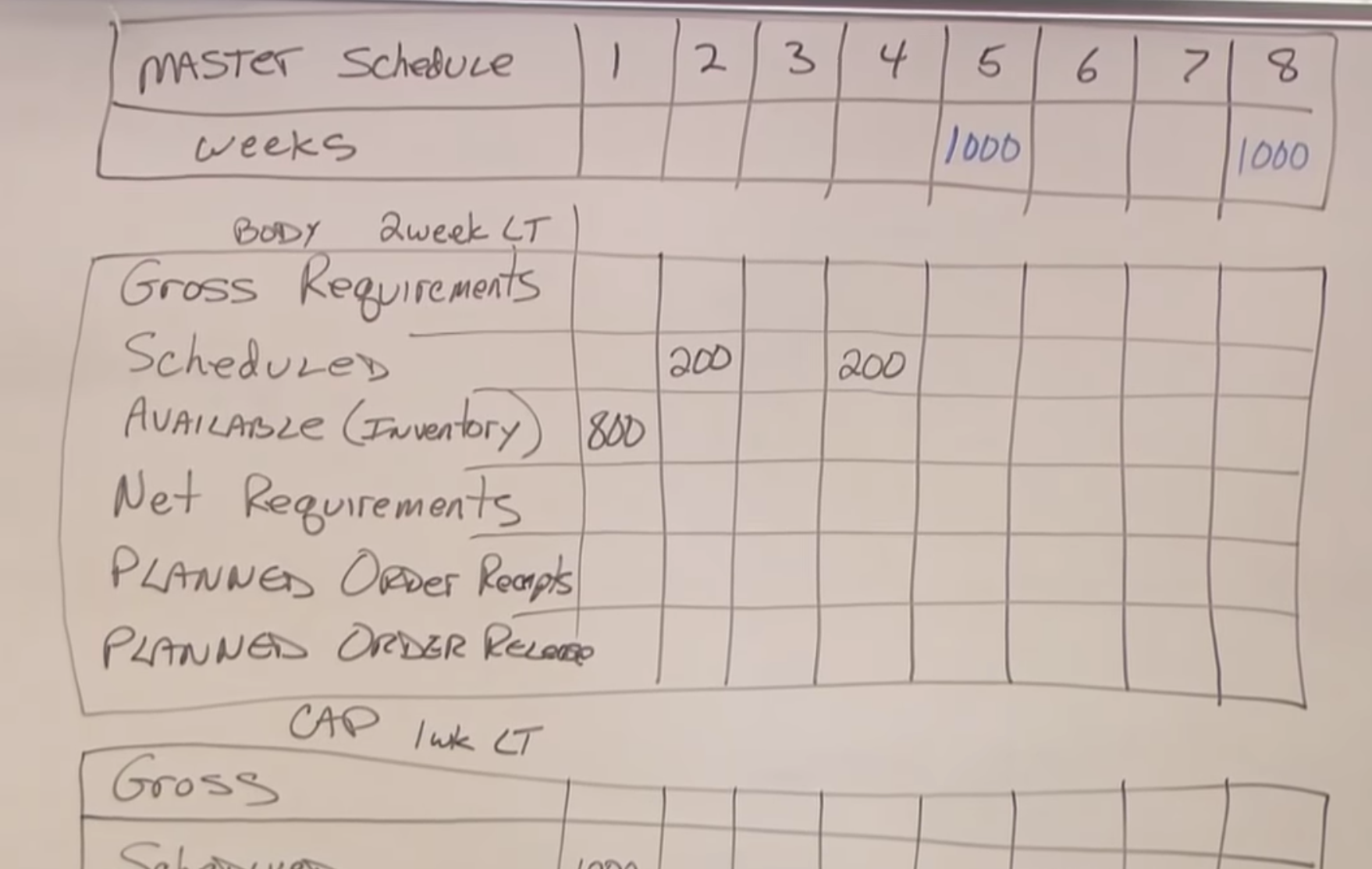

Inventing material requirements planning is a way to algorithmically manage the production process as a way to better manage the sprawling production needs of large companies. By 1980, material requirements planning saw widespread adoption. Personnel calculated inventory turns, requirements, and min-max points manually.

As the computer age dawned, affordable computing power allowed for increasingly complex material requirements calculations. A natural next step for manufacturing planning was to teether manufacturing planning to financial resources, and potentially customer and employee management. Thus, ERPs (Enterprise Resource Planning Systems) were born.

ERPs as a Robust Industry

Enterprise resource planning means the integrated management of main business processes. Each module of the ERP system was necessarily complex and as time went on adds more modules. The consultants charged with installing these solutions were typically selling the ERP system as a cure-all for businesses.

We can handle all of your human resources, CRM, manufacturing, and project needs. Trust us!

In certain instances, an ERP system’s ability to dictate operating protocol was a net benefit to the client. Well-defined processes stabilized poor business practices and provided a strong framework for growth. Unfortunately, a single ERP package cannot define operating protocols for all people. For example, let’s investigate the simple process of receiving an inbound shipment. That shipment, receive and push to a quality lot if it meets certain parameters, conduct tests, and return the asset to standard inventory if the test passes.

Enterprise software can easily define the simple process of inbound receiving but struggles with nuanced and complex tasks such as a quality check. A typical result? Loads of supplemental Excel spreadsheets to track the required measurement data.

The One Size Fits All ERP Era

The one size fits everything ERP solution was a winner take all game in the 1990s and 2000s. Thus, ERP companies postured as a 100% solution and built product roadmaps around that claim. Thus, with this framework in place, software companies receive incentives to sell everything and the kitchen sink to win a client’s heart. As such, SAP long argued:

“SAP R/3 overcomes the limitations of traditional hierarchical and function-oriented structures like no other software. [All the functions] are integrated into a workflow of business events and processes across departments and functional areas…”

To sell a single program as a one size fits all solution is a tough value proposition, seeing an ERP system, construct to define hundreds and perhaps thousands of processes. A 98% fit-for-purpose success rate in doing so is admirable. But what happens to the dozen or so processes that aren’t appropriately defined? Is it time to advocate for manual spreadsheet intervention?

The ERP API

In 2005, APIs (application programming interfaces) made it out of the backrooms and into the common business vernacular. APIs allow critical data to be delivered to a client or application without the need for middleware. As of 2019, three-quarters of organizations are developing internal and publically facing APIs to allow systems to talk to each other in a seamless, efficient way.

What the Advent of the API Means for ERP Systems

An ERP software appropriately enabled with APIs can still claim to provide all of a client’s needs while easily engaging smaller, agile programs should the particular needs arise. Let’s take another look at the example of receiving an inbound shipment.

That shipment is received and pushed to a quality lot if it meets certain parameters, tests are conducted, and the asset is returned to standard inventory if the test passes.

In the prior example, a supplemental worksheet was used to collect data outside of the enterprise system. With API empowerment, a simple web or mobile application using specialized measurement data can collect the required data and then easily deliver mission-critical data to the ERP system. Thus, this system flexibility allows a simple specialized tool to deliver the required information quickly and efficiently. No customization of the ERP or manual Excel spreadsheets required.

We have entered an incredibly interesting period for manufacturing and distribution. Many decision-makers in these industries still remain unaware of the power and flexibility that an ERP API grants them in designing and executing a robust management system. However, great ERP system with robust API integration will make sure you never have to pick between a person monitoring an unconnected Excel spreadsheet and or a piece of lumbering software.

Want to know more about how to effectively leverage APIs in your business? Drop us a line!